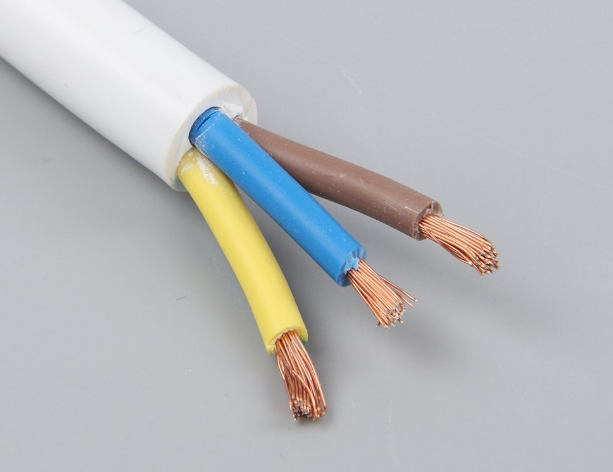

Tech 2/3 diameter diameter refers to a specific measurement standard used in various technological fields to enhance precision in manufacturing, design, and product development. The term “diameter” is commonly associated with the measurement of a circle’s width, but in the context of “tech 2/3 diameter diameter,” it relates to a refined approach for achieving accuracy in production. The 2/3 notation indicates a specific proportion of the diameter in the design, making it essential for achieving optimized performance, especially in highly engineered products like robotics, aerospace components, and consumer electronics. This precise measurement standard has become a cornerstone for innovation in many industries, ensuring that each part fits perfectly, operates efficiently, and meets stringent quality control standards.

Importance in Modern Technology

In modern technology, small variations in diameter can significantly impact performance. The tech 2/3 diameter diameter standard ensures that every component fits as intended within larger systems, leading to enhanced efficiency, durability, and functionality. Whether in advanced robotics or sleek consumer electronics, the consistent application of this standard allows for smaller, more powerful devices with greater precision. The importance of tech 2/3 diameter diameter extends beyond simple measurement—it plays a critical role in ensuring that complex systems are both functional and reliable. As industries continue to push the boundaries of innovation, achieving accurate diameter measurements is becoming more crucial than ever.

Brief History of Diameter Measurements in Tech

Diameter measurements have evolved significantly throughout history, from basic mechanical applications to complex digital systems in modern technology. Initially, diameter measurements were essential in mechanical engineering to ensure parts meshed seamlessly in machines. As technology advanced, precise diameter measurements became crucial for developing smaller, faster, and more reliable devices. The introduction of tech 2/3 diameter diameter marked a leap forward in terms of precision and efficiency. This refined standard has enabled companies to produce products with tight tolerances, which has led to improvements in everything from the automotive industry to cutting-edge electronics. Over the years, this measurement technique has become ingrained in engineering practices worldwide.

Why Tech 2/3 Diameter Diameter is Crucial for Innovation

Role of Diameter in Technological Advancements

Diameter plays a pivotal role in numerous technological fields, particularly in engineering and design. It serves as a fundamental parameter for determining the size and fit of parts, ensuring that products function as intended. In tech applications, achieving the correct diameter is crucial to the performance of machines, sensors, and devices. The tech 2/3 diameter diameter standard takes this a step further by ensuring that components meet precise tolerances, allowing for greater consistency and reliability. For example, in robotics, an accurately measured diameter in gears, shafts, and motors ensures smooth operation and minimal wear over time. Without this level of precision, the functionality of high-tech systems would be compromised, leading to inefficiency and failure.

Applications in Various Tech Sectors

Tech 2/3 diameter diameter has found applications in a wide range of technological sectors. In aerospace, for example, components such as turbine blades, engine parts, and structural elements rely on accurate diameter measurements to ensure performance and safety. Similarly, in robotics, the precise fitting of joints and parts allows for smoother movement and better interaction with the environment. Consumer electronics, such as smartphones and laptops, also benefit from tech 2/3 diameter diameter measurements, particularly in the design of connectors, chips, and internal components. The ability to consistently measure and control diameter in these products leads to smaller, more efficient devices that deliver better user experiences. Overall, tech 2/3 diameter diameter has become a crucial standard for achieving precision across various industries.

The Evolution of Diameter Measurements in Technology

Historical Development of Diameter Use in Tech

The concept of diameter measurements has existed for centuries, but its application in technology has drastically changed over time. Initially, diameter was used primarily in mechanical engineering to measure basic geometric shapes. However, with the advent of industrialization and technological advancements, the need for more accurate and standardized measurements became evident. In the 20th century, as machines became more complex and automation grew, precise diameter measurements were essential to maintain quality control. The introduction of digital tools and advanced manufacturing techniques further pushed the boundaries of accuracy, giving rise to standards like tech 2/3 diameter diameter. Today, this measurement system ensures that parts fit together seamlessly in high-tech industries, making it indispensable for innovation.

Impact of Diameter on Modern Tech Standards

In the modern tech landscape, diameter measurements are essential for ensuring that components are designed and manufactured to exact specifications. The introduction of tech 2/3 diameter diameter allowed for a more refined level of accuracy, which was previously unattainable with older measurement techniques. As technology continues to evolve, so too does the importance of these precise standards. From robotics to AI, the precision enabled by tech 2/3 diameter diameter supports the functionality and reliability of cutting-edge products. The rise of miniaturization in consumer electronics also relies on this measurement standard to produce smaller, more powerful devices. With tech evolving at a rapid pace, achieving the correct diameter is fundamental to maintaining high-quality standards in product development.

Also Read: Unity 2022.3 Oculus Link Constant Hourglass Windows 11

How Tech 2/3 Diameter Diameter Optimizes Design

Benefits for Engineers and Designers

For engineers and designers, the tech 2/3 diameter diameter standard brings a host of benefits, primarily by enhancing precision in the design and manufacturing phases. Achieving the perfect fit for every component can be the difference between a successful product and a failure. The ability to apply a precise diameter measurement allows for better integration of parts, reducing errors during assembly and minimizing the need for adjustments post-production. This not only saves time and resources but also leads to products that function more efficiently. Furthermore, it aids in the optimization of product longevity, as components are less likely to wear out prematurely due to poor fitting.

Tech 2/3 Diameter Diameter in Product Prototyping

In product prototyping, the application of tech 2/3 diameter diameter ensures that designs are validated with a high degree of accuracy. Prototyping is a critical phase in product development, and any inaccuracies in diameter measurements can lead to design flaws that are costly to fix later. By adhering to precise diameter standards, designers can test prototypes that closely mirror the final product, making the testing phase more effective. This accuracy also helps in identifying potential issues earlier in the process, saving valuable time and effort during development. As a result, companies are able to deliver high-quality products that meet consumer expectations more efficiently.

Tech 2/3 Diameter Diameter in Robotics and Automation

Precision in Robotic Engineering

In robotic engineering, the application of tech 2/3 diameter diameter is crucial for ensuring that the mechanical components, such as gears, actuators, and sensors, work together with a high degree of precision. The smallest miscalculation in diameter can result in mechanical failure, loss of efficiency, or decreased performance over time. By using this refined measurement system, engineers can guarantee that parts mesh perfectly, ensuring smooth operation and reducing wear. This level of precision is particularly important in industries where robots perform intricate tasks, such as in medical surgery or high-precision manufacturing. The ability to achieve accurate diameter measurements directly contributes to the reliability and longevity of robotic systems.

Automation and the Need for Accurate Diameter

The rise of automation has amplified the need for tech 2/3 diameter diameter in industries where precision is paramount. Automation systems rely on the seamless interaction of hundreds or even thousands of parts, each with carefully measured diameters. Whether it’s in assembly lines or advanced manufacturing environments, accurate diameter measurements ensure that automated systems operate with minimal errors. Without this level of precision, automation could lead to costly mistakes, inefficiencies, and reduced productivity. As automation technology continues to advance, the importance of accurate diameter measurements will only grow, further solidifying tech 2/3 diameter diameter as a key standard in the tech industry.

The Role of Tech 2/3 Diameter Diameter in Aerospace

Aerospace Engineering and Critical Measurements

In aerospace engineering, precision is a matter of safety, and the tech 2/3 diameter diameter standard is integral to ensuring that every component, from engine parts to structural elements, meets rigorous performance criteria. The smallest deviation in diameter can have catastrophic consequences in high-pressure environments like spacecraft or jet engines. By applying tech 2/3 diameter diameter, engineers can manufacture components that fit together perfectly, reducing the risk of failure and ensuring the overall integrity of the vehicle. This standard is essential for maintaining the high-performance levels required in aerospace applications, where precision is a non-negotiable factor.

Enhancing Durability and Performance

The durability and performance of aerospace components are directly influenced by the precision of their diameter measurements. Parts that are too large or too small can cause unnecessary wear and tear or affect aerodynamics and fuel efficiency. Tech 2/3 diameter diameter ensures that components are manufactured within strict tolerances, allowing them to perform optimally and last longer. In the competitive world of aerospace engineering, the ability to create parts that are both lightweight and durable is a significant advantage. By adhering to this measurement standard, aerospace manufacturers can produce components that contribute to the overall efficiency and reliability of their vehicles.

Tech 2/3 Diameter Diameter in Consumer Electronics

Smartphones, Laptops, and Everyday Devices

Consumer electronics, including smartphones and laptops, are increasingly relying on tech 2/3 diameter diameter for their design and functionality. The components within these devices, such as chips, connectors, and screws, require precise diameter measurements to fit within the tight spaces available. The tech 2/3 diameter diameter standard enables manufacturers to create smaller, more powerful devices that deliver better performance without compromising on size or design. In the competitive world of consumer electronics, the ability to achieve accurate diameter measurements can make a significant difference in the overall user experience, allowing manufacturers to stay ahead of the curve in terms of innovation and quality.

Improving Device Longevity and User Experience

The precise application of tech 2/3 diameter diameter not only improves the performance of consumer electronics but also enhances the longevity and overall user experience. When components fit together perfectly, devices are less likely to experience issues like overheating, wear, or breakage. This increases the lifespan of the product and ensures that users enjoy a seamless experience throughout the life of the device. Furthermore, accurate diameter measurements contribute to better signal strength, faster processing speeds, and improved battery life, all of which are key factors in creating highly efficient consumer electronics.

How Tech 2/3 Diameter Diameter is Used in AI Development

AI Hardware Components and Precise Measurements

Artificial intelligence (AI) relies on advanced hardware components, many of which require precise diameter measurements for optimal performance. Processors, sensors, and memory chips used in AI systems must adhere to exact standards to ensure that they operate efficiently and communicate effectively with other components. The tech 2/3 diameter diameter standard plays a significant role in ensuring that these hardware components are manufactured to the exact specifications required for AI systems to function at their best. By maintaining strict control over diameter measurements, manufacturers can create AI hardware that delivers faster processing, more accurate data analysis, and better overall performance.

The Future of AI and Diameter Optimization

As AI continues to evolve, so too does the need for precision in hardware manufacturing. The tech 2/3 diameter diameter standard will likely play an even more prominent role in the development of future AI systems, enabling manufacturers to create smaller, more powerful chips and processors that can handle increasingly complex tasks. This optimization will be essential as AI becomes more integrated into everyday life, from autonomous vehicles to personalized healthcare solutions. By improving diameter accuracy in AI hardware, tech companies can ensure that AI systems operate at peak performance, pushing the boundaries of what is possible in the field of artificial intelligence.

Conclusion

Tech 2/3 diameter diameter has revolutionized multiple industries by providing the precision necessary for high-performance engineering, manufacturing, and design. As technology continues to evolve, this measurement standard will play an increasingly important role in shaping the products of tomorrow. Whether it’s in robotics, aerospace, or consumer electronics, the ability to achieve such precision allows for the creation of smaller, faster, and more efficient devices. Moving forward, the importance of accurate diameter measurements will only grow, driving further advancements in technology and ensuring that innovation continues to thrive across various sectors.